We arrived at the BiniVista vineyard on a gorgeous winter morning, the warm sun reflecting artfully in rain puddles along the red dirt road which led through the young vineyards to a few unassuming stone and plaster buildings. In the distance, construction activity bustled; but before we could wonder about it, we were greeted by our tour guide, none other than the BiniVista Winery Danish co-owner and founder, entrepreneur Søren Svenningsen himself. This was more than a treat for us, because for the following hours this passionate and inspiring host shared the heart of the winery’s inception, dreams, intelligent steps, and laser focused plans. It doesn’t get much better for us than to be completely immersed in winery details and workings, and Søren was a steady wealth of information and enthusiasm.

Soren and his closest friends have cycled Mallorca for decades. Then in 2017 dreams and ideas started germinating for a Members Only winery with great wine, a kindred-spirit community, cycling experiences, art exhibitions, wine tastings, education, cooking for pairing, and more! All these will be enjoyed on site or on island, with wines distributed twice a year exclusively to members in Denmark and Spain.

But before any of that could happen, they knew they had to grow the best wine grapes possible – “Because of course,” Soren said “the full potential of a wine is only as strong as the grape!”

They bought a 21-hectare almond grove with an enormous natural well, removed the trees, and allowed the land to lay fallow as their plans grew. Cycling Mallorca in the mornings and studying in the afternoons, Soren trained extensively in wine making and tasting, worked with specialists, and the team tasted hundreds of wines together in this planning stage. Soren told us that they consistently considered the organic wines to taste best, which is such a testament to nature! In March of 2018 they planted 80,000 vines, including 11 grapes with the specific plan of 100% organic wine.

Ingeniously, in the planting stage they defied tradition: Instead of planting their vines East-West for maximum sun exposure as is standard, they were confident of sufficient sun on Mallorca, and planted North-South to take advantage of the winds coming down from the Tramontana Mountains to aerate the plants and keep the plaguing molds down naturally. They pulled the largest rocks from the soil in order to cultivate deeply, producing a 40 meter high pile of stones they used for facing the new facility and laying into the extensive property dirt roads! Importantly, because of this they were then able to lay in a groundbreaking American deep subsoil-irrigation system (thus encouraging roots to seek downwards while keeping humidity away from vine trunks) and a-symmetrically creating partial root drying (to signal the plant to take advantage of water availability). Water makes good leaves, and drought signals to the plant to move water to the fruit; so the BiniVista team planned perfectly controlled water delivery after leafing is mature and precisely when the plant recognizes the arrival of water as necessary to benefit its fruit. 2018 was a hot year on Mallorca, requiring huge amounts of water for the new vines, but their well was ample!

To their astonishment, their eco-friendly design worked faster than expected. The plants flourished and fruited the first year, and they needed to harvest and could make their first wines the next year in 2019! Not having planned this initial harvest to be viable, their processing facilities were not complete! So, they worked with our friends Miguel and Jaume Fullana at Bodega Es Verger and bottled 10 thousand kilos of their three grape varietals of Sauvignon Blanc, Merlot, and Grenache grapes. In 2020 Søren bought and planted 5 additional hectors bringing the total to 26 hectares now planted with 100 thousand vines of 12 different grapes. Always growing and learning, after tasting their 2019 Gorgollasa grape wines, they did not release them. Planting local Mallorcan grapes like Gorgollasa has been popular recently, which is wonderful, but after tasting their Gorgollasa wine, and others coming onto the market, they decided to go in a different direction and grafted those vines with Merlot!

From the beginning, no machines ever touch their grapes! All are 100% hand harvested, but they do machine plow the surface of the wide rows to keep weeds and horizontal vine roots to a minimum. This purposeful combination allows them to remain organic, with naturally healthy plants!

The original plans were for their first harvests to be 13 grapes for 7 wines in 2020 and 2021, in a dynamic new facility – but 2020 was upon them and the building licenses for their processing facility were not all passed yet (in island style) and construction was not complete! In another tour-de-force move they made ready in the charming small facility we now toured, outfitting the small storerooms with state-of-the-art equipment: The best grapes deserve the best conditions to make the best wine, which is exactly and overtly the BiniVista team plan.

And who is “the team?” Entrepreneur and founder Soren Svenningsen, Mallorcan grape specialist and winemaker Jaume Fullana of the Bodega Es Verger family, Mallorcan Joan Horrach a pro-cyclist and the BiniVista staff and property manager, and Danish marketing and sales specialist Marie Von Ahm based in Barcelona. Recently, Jaume Fullana has moved on to other projects and the German oenologist and winemaker Julie-Nora Lorenzen has joined the team. They are not Certified Organic as of this writing, because they have only been producing wines for two+ years, and so are waiting to complete this third year in order to be classified.

Walking through the ample vine rows that beautiful morning, Søren told us that from the beginning they were intent on fully understanding and working specifically with the sugar and acidity content of their grapes. There is almost no sugar in April when the grapes begin to ready, and the acidity is high, so the game is waiting while sugar rises and acidity reduces to the perfect point for their taste. Every summer season as the heat increases and water leaves the grapes, sugar goes up, but the acid may still be too high. That is when the BiniVista team begins testing the grapes regularly, by green-harvesting out crowded bunches so the plant can focus on the remaining fruit, and they begin watering accordingly. The plants that have been preparing for drought react to the summer water and actively put the water into the grape where the winemakers want it. Voila! The grapes mature longer on the vine, and the team tests vigilantly as the acidity level continues to drop to their perfect ratio point for harvest.

Each July the staff workers hand-prune out the last of the unwanted bunches, and in August they hand-harvest the 100 thousand vines, hiring only a few outside workers that are known to them in order to allow the harvest to be picked in precise time. Harvesting in the heat of a Mallorcan August day, the grapes are hot! So each shallow hand-picked flat is immediately placed in the cool chamber, and slowly brought to 10 degrees Celsius to preserve the maturity point and control fermentation. Within 24 hours of picking the harvest, processing begins! The first job is to carefully sort and cull each and every bunch by hand, with selection based on ripeness (and thus sugar or acid content). The chosen grapes are then destemmed, because the BiniVista recipes do not include stem tannins or flavors!

All of the production equipment in the small space we toured was new and very high quality, like the elegant balloon press that allows delicate pressure control for soft press, so seeds don’t crush and release their tannins and flavor. Their primary goal throughout processing is temperature and oxygen control, as well as hygiene so no external elements can affect the flavors. They use a peristaltic pump and tangential flow filtration to ensure the wine the softest treatment and avoid adding oxygen in the process. Soren assured us that because of all the testing they did in the beginning, they now know exactly what they are going for; and the more control, the better the wine. They are making an honest wine, they don’t add acid, so careful processing is critical.

Soren told us grapes are like humans: All grapes are the same color inside, only the skin is different – we loved that! So, we were reminded that a Blanc de Noir wine (white from Black/red grape) is a white wine made from red-skinned grapes! This requires a quick soft-press, so that none of the color of the red skin is crushed into the clear must/juice. During the processing of red wines, wine makers include the red grape skins and leave them long enough to allow the color they desire, but for BiniVista, a soft press is still essential with red grapes to avoid seed flavor. With white grapes for white wines, the skins can be left with the juice for awhile if the skin-tannins are desired. We learned something else we had both been wondering about: The term ‘orange wine’ has become more popular recently, and Soren explained that it is called that because winemakers purposefully ferment white grapes with the skins, which ultimately affects the color producing an orange hue. Soren told us that BiniVista will not make an orange wine, because he and the team don’t like the flavors produced by the tannins from the skins.

We also learned that Spain alone consumes 70 million liters of white wine each year, but they do not produce that many white grapes, so many Spanish whites are actually Blanc de Noir. And we learned that Spanish Cava, the sparkling wine sister of Champagne, is normally a Pinot Noir grape Blanc de Noir blended with Chardonnay! Live and learn on the Mallorca Wine Trail!!

Arriving to the lovely small tank room, we learned that for white and rosé wines they allow the grape seeds and skins 1-2 days to settle at a low temperature to prohibit fermentation at that time. They then move the must/juice carefully and hygienically to the next tank, away from that sediment. This moving from tank to tank is known as racking the wine. Afterwards, all sediment is collected and taken away (and we thought “Hello organic compost for someone!”).

The only thing BiniVista winemakers add to their wines at this time is organic yeast, and soon they will be cultivating their own indigenous organic yeasts on the property, since each grape has its own yeast. Some winemakers think these native yeasts are a truer expression of terroir, and make the wines more distinct. Yeast helps convert the sugar in grapes into alcohol and carbon dioxide during the fermentation process, and some yeasts can add pleasantly to the aroma. Careful manipulation of the yeasts helps achieve each winemaker’s desired results, and the BiniVista team has clear and specific intentions. In their German tanks with cooling jackets (a layer of cooling water), BiniVista uses the lowest temperature possible for their yeasts to work, so fermentation isn’t accelerated. Whites and Rosés get about 10 days with yeast, and then the wine is racked away from all yeast sediments and into the next clean cool tank. The clear must/juice now sits in this tank and finds itself. The team monitors the flavors as each wine equalizes and stabilizes its particular characteristics and structures.

Wine structure refers to the main characteristics of a wine that one considers while tasting: acidity, sweetness, body (viscosity), tannins and alcohol. Many things, including racking, filtering, bottling, temperature and transport can upset wine structures. BiniVista bottles their Whites and Rosés in February, always paying close attention to temperature, oxygen and hygiene so that what they bottle is exactly as intended: Great wine for great members!

Soren described that reds are much more difficult to process. They don’t rack these. In the current buildings they allow the wine 1-2 days to settle, then add yeast, and then punch down the skins and must-off the cap (or hat) by hand. CO2 created in fermentation pushes the skins back up, and so they punch down three times. BiniVista also uses manual punch down/pigeage (where grapes are mixed with the must/juice) and pump over (where the wine is gently moved over the cap to soften it) 2-3 times a day during fermentation, for a full week of manually mixing the cap. If it’s done by machine it brings in additional oxygen and possibly bacteria, both of which affect flavors.

An aside, some definitions for readers:

The cap or hat (sombrero in Spanish) is the solid mass of grape skins and seeds (and stems at other wineries) that floats to the top of the fermenting tank as the red wine ferments. Punching down or pigeage is the process of breaking up the cap and pushing it back down into the wine so that the cap stays moist during fermentation allowing the wine to gain a richer color, flavor, and tannin structure. Punching down also helps mix the yeast into the must (the juice). It helps keep harmful bacteria or mold from forming that could ruin the wine. It also helps dissipate heat that naturally occurs during fermentation. Otherwise, the cap can reach high temperatures and provide an environment that could grow harmful bacteria.

After 2 weeks they remove the cap and adjust the temperature to allow alcohol fermentation and then malolactic fermentation in the stainless tanks. Once the wine is mature, it is then put in barrel to absorb oak notes, and to breath in wood the way it cannot in a sealed stainless tank.

Continuing on to see the barrel room, we learned more about the Members Only ideology, and how membership ideas and wine deliveries were evolving. Soren told us their goal is for no more than 1000 members. Until this year they have been producing enough wine for about 350 members, and membership is already at 300; but in 2021 they harvested 80,000 kilos of grapes, so growing the membership is possible now, for distribution when these wines are ready soon. Currently, membership includes full access to the winery for education and enjoyment, and two deliveries of 20 bottles anywhere in Denmark or Spain. Spring deliveries include 1 rosé, 2 whites, and fresh red that has spent less time in barrel. The Fall delivery includes 4 reds. There will be Chef run cooking and pairing classes, tastings, art exhibitions, cycling and wine events. And they are planning in timeshare residences for interested members at the vineyard, based on a current Danish tradition called 21-5: where 21 people share 5 places to keep costs down on being able to travel to desired destinations five times a year!

In 2021, Soren decided his intention was no longer simply to grow the best grapes, but solidly to make the best wine! And he knew that to do so he would have to have complete control of the entire process. And so, he contracted with engineering and consulting company Alfatech from Madrid which specializes in building and designing high quality wineries around the world. Soren purposefully tripled his budget for building their new processing facility and Club House: His intention was no longer simply to make the best wine It was now to have the most sophisticated and modern winery internationally possible

Still hearing excavators and fork lifts chattering nearby, we headed on foot along the red dirt road to tour the new, state-of-the-art facility.

As remarkable as it was for us to imagine as we walked through the open building site, their new construction was slated to be done in four short months from the time of our visit – by May 1st 2022, with a Grand Opening in September!

Needless to say, the entire new facility is temperature and humidity controlled – with solar panels designed into the roofs to support the advanced electrical systems within – beginning with the grape cooling chambers to allow the hot summer-harvested grapes to lower gently to the cool-point where they can no longer develop in their acid-to-sugar ratio.

They have two peristaltic presses now, and when their plans expanded, they actually re-applied and were permitted to raise the ceilings so that they can use an elevator to transfer sorted and destemmed grapes into the presses and then to the tanks, using a gravity feed system so they never have to pump (which we had learned can affect the wine structures!). And the biggest change is that they now own tanks, and tank rooms, where they can completely control temperatures from beginning to end.

In the new tank room, they designed tank-access holes into the above-tank walks for the pigeage of their reds. Also, the punch-down pumps are within the tank, so punch-down and pump-over are achieved in a closed, hygienically stable system! Both processes are fully automatic, and pigeage is done like a press-coffee system with two cylinders that gently press the cap of grape skins into the must/juice.

With their new tank system they are able to clear their wines by temperature, not chemicals, leaving the must protein structures virtually unaltered and stabilized before bottling!

And after desired fermentation is complete, their white wine can be stored in-tank for any amount time needed before bottling, because fermentation can be completely suspended in these temperature-controlled tanks.

Walking through the humming construction site, Søren told us that the new building design is all about pipes and thermostats for the hydrogen cooling – which we could clearly see for ourselves with all the open ceilings and floors!

BiniVista is currently set to produce 150 thousand bottles per year and 300 thousand liters. In the near future they will be able to produce for other winemakers as well – but they will not buy outside grapes for BiniVista wines.

When done, they will have their own in-house lab for testing, and their bottling room will have complete control including hydrogen insertion equipment for under the corks instead of allowing in air. They will have a large freight elevator for equipment and moving in tanks etc., and tank room floors are being built with drainage and stone tile for hygienic cleaning. The bottle maturing room will be underground with temperature and humidity control, and for members and business clients, there will be a tasting room with a big picture window into the attractive barrel room.

In the barrel room they are planning for 200 barrels of 500 liters each, using French oak from Bordeaux and Burgundy, and some wines in larger barrels for softening tannins through the micro-oxygenic natural breathing of oak (true of corks as well). Conversely, they keep their Grenache wine in steel tanks because, unlike most other reds, it does not have a lot of tannins. As part of their design, some of their reds spend more time in bottle than in barrel to keep a desired tannin structure. Additionally, as it is necessary to open barrels for testing which can introduce bacteria, they feel that tank resting is desirable when possible. Alcohol and Malolactic fermentations can be controlled and facilitated by strategic tank, barrel, and bottle stages. Soren told us that here they do barrel resting for no more than 3 years, per their BiniVista palette.

The new facility will sport innovative architectural details such as the barrel room visible through glass beneath upstairs tasting tables, a gallery for art exhibitions, a kitchen for chef prepared food and pairing classes, and exterior terraces for outside events with magnificent views of the vineyard and Tramuntana mountain-range.

We were enjoying that view ourselves as Soren told us that they named the winery BiniVista exactly for those views. In Mallorca there are many towns that start with the word ‘Bini’ and after some research he learned that these towns go back to the approximate 327 year Moorish occupancy which ended in the year 1231. ‘Bini’ means ‘son of’ or ‘home of’ in Arabic, hence BiniVista means ‘home of the view.’ And this is where cycling comes back in! Soren told us that most professional cyclists who train and ride this island know the mountains by name, use them as landmarks, and aspire to ride to the tops when possible – so at BiniVista every wine is named after a mountain in that view, but with a little twist…

The twist is that the Counsel of Mallorca refused to allow them to actually name the wines after the mountains, because the grapes weren’t grown on those mountains. So, the BiniVista team came up with a variation on that theme and named the wines the degrees the mountains lie from the winery: So for example, their white wine named 15° is named so for the peak of the mountain Tomir, because their Sauvignon blanc vineyards are facing this mountain at the angle of 15° from the winery. And they put QR codes on each label with information about the namesake peak! Ingenious! But more about that when we get to the tasting…

And here was where the fun really began! For a careful and thorough hour we tasted two whites, one rosé, and 4 reds; and if the paired tapas and palate-enhancers laid out to accompany our tasting are any indication of what members have in store for them, then all will feel like royalty, as we did! It really is remarkable to savor a given wine, clear the palate with a neutral biscuit, shift it with a great local cheese, or pair it with a favorite flavor: showing the many faces of a single quality wine.

As we tasted, Søren shared what he and the team are looking for in their wines.

They are striving for:

Søren told us that complexity happens first from the earth, the terroir, with the root pulling minerals into the grape; secondly at the winery during fermentation and processing, and finally in the bottle where notes such as tobacco and earth integrate and the wine finalizes.

A word about terroir: Soil that is depleted loses its natural, geographical terroir and the unique qualities that provides. So we on the Mallorca Wine Trail encourage all wineries to read up on protective and regenerative agriculture to protect the biodiverse Mallorcan native terroir!

Søren told us that young reds need more breathing time before tasting, and that all reds should be decanted. All the BiniVista reds go to barrel except Callet which they use to blend because of its spicy notes.

And Søren also showed us their website, and how the bottle QR codes work. They have done a thorough and engaging job with their site which fully supports the idea that they want the members to feel it is their winery!

All the wines we tasted were nicely balanced on the dry side, with even sugar-to-acid integrity. Reminding you again about the wine names, each wine is named in honor of a specific local mountain and it’s orientation to the winery. So the wine Tomir 15° is named after the Puig de Tomir which lies at a 15 degree angle to the BiniVista Winery; the word Puig (pronounced ‘Pootch’) being the word for mountain in Mallorquin. The website descriptions of these Mallorcan mountains certainly makes a body want to pack a picnic with good wine and cycle or hike to the peaks!

We tasted:

1. White #1: Puig de Tomir 15°: 60% Sauvignon Blanc, 40% Viognier. Nice bright acidity from the Sauvignon Blanc, good body and fruit from the Viognier, crisp with subtle earth notes. The particular bottle-year we tasted is 14% alcohol because that summer was so hot, and the BiniVista team did a fine job of balancing the alcohol with the wine’s other properties. We all agreed this is a lovely wine to enjoy in the kitchen while cooking and to pair with appetizers!

2. White #2: Puig de Galatzo 265° – 54% Chardonnay, 30% Giro Ros, 16% Callet. This is a full-bodied and complex white, ripe fruit flavors forward. The red Callet grape lends a hint of color and local grape character. This wine will readily compliment any meal and can easily stand alone as well.

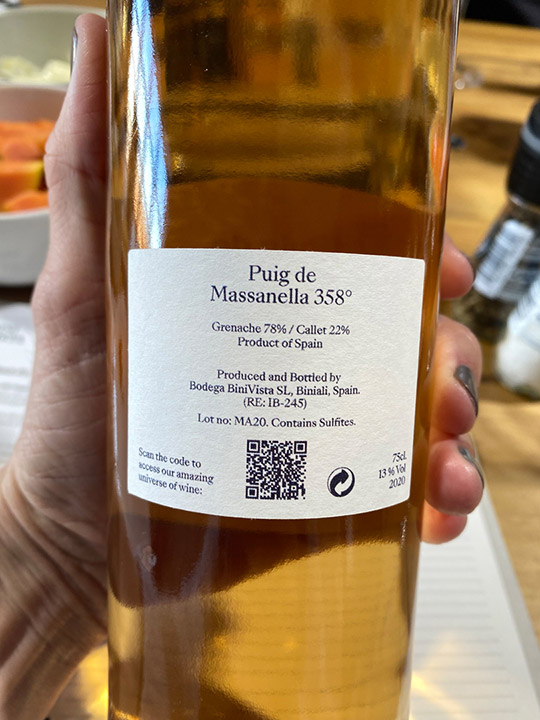

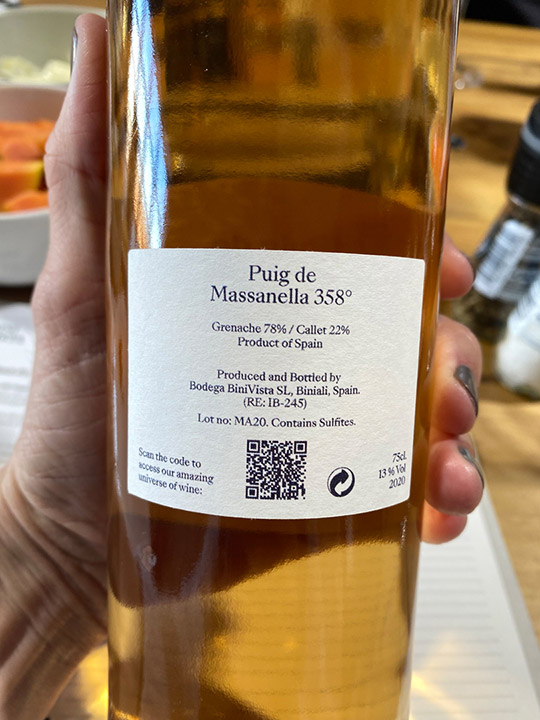

3. Rosé: Puig de Masanella 358° – 78% Grenache, 12% Callet. Showing a gentle amber color rather than signature rosé-pink, this satisfying wine has the body of ripe Grenache accented by a fanciful dash of Callet added just before bottling. This delicious wine satisfies like a red, but is crisp like a refreshing white, and suited for any meal or refreshing sipping occasion.

BiniVista_2022_MWW_078

4. Red #1: Puig de Randa 157° – 100% Pinot Noir. This wine is full bodied as Pinot’s from a hot climate can be, and the team got the complimentary oak notes just right. It is blended carefully from select barrels of the same harvest – not all barrels fit the bill!

5. Red #2: Puig de Teix 296° – 50% Pinot Noir and 50% Callet. The barrels of Pinot not used for Randa 157° were used in Teix 296°! Blended equally with tank matured Callet, this is a delicious, juicy red with a vibrant character all of its own.

6. Red #3: Puig de Santa Magdalena 48° – 35% Syrah, 31% Grenache, 26% Callet, and 8% Pinot Noir. The team must have had fun with this blend, and the result is a robust, complex and very drinkable red wine.

7. Red #4: Puig de Sa Rateta 334° – 100% Syrah. Pure Syrah yes, but made from grapes from three different plots, harvested on different dates, combined after malolactic fermentation and put into new French oak to integrate into this satisfying, rich red wine. Syrah lovers will find this vintage a treat.

At the end, and perhaps because we were so enthusiastic about all of the BiniVista wines we had tasted, Søren treated us to a tasting of their first 2019 red from the 2018 planting: 296° Puig des Teix 1062m! How extraordinary and downright special to taste a wine from such young vines! This vintage was a blend of 91% Grenache and 9% Merlot, medium bodied, characteristically dry, with expressive fruit flavor! Then to top even that, we took a stroll back to the small, temporary tank room for some 2021 rosé wine still coming to know itself! Served right from the tank tap, it was young and bright, with a mouthwatering quench and good structure forming. We can’t wait until bottling and release to get to know it better ourselves!

BiniVista Winery: Balanced, complex, intense and enduring – what a great way for Tawnee and Merie to continue our adventures on our Mallorca Wine Trail this year!

2 Whites

Puig de Tomir 15°: 60% Sauvignon Blanc, 40% Viognier

Puig de Galatzo 265° – 54% Chardonnay, 30% Giro Ros, 16% Callet

1 Rosé

Puig de Masanella 358° – 78% Grenache, 12% Callet

4 Reds

Puig de Randa 157° – 100% Pinot Noir

Puig de Teix 296° – 50% Pinot Noir and 50% Callet

Puig de Santa Magdalena 48° – 35% Syrah, 31% Grenache, 26% Callet, and 8% Pinot Noir

Puig de Sa Rateta 334° – 100% Syrah

Nice bright acidity from the Sauvignon Blanc, good body and fruit from the Viognier, crisp with subtle earth notes. The particular bottle-year we tasted is 14% alcohol because that summer was so hot, and the BiniVista team did a fine job of balancing the alcohol with the wine’s other properties. We all agreed this is a lovely wine to enjoy in the kitchen while cooking and to pair with appetizers!

This is a full-bodied and complex white, ripe fruit flavors forward. The red Callet grape lends a hint of color and local grape character. This wine will readily compliment any meal and can easily stand alone as well.

Showing a gentle amber color rather than signature rosé-pink, this satisfying wine has the body of ripe Grenache accented by a fanciful dash of Callet added just before bottling. This delicious wine satisfies like a red, but is crisp like a refreshing white, and suited for any meal or refreshing sipping occasion.

This wine is full bodied as Pinot’s from a hot climate can be, and the team got the complimentary oak notes just right. It is blended carefully from select barrels of the same harvest – not all barrels fit the bill!

The barrels of Pinot not used for Randa 157° were used in Teix 296°! Blended equally with tank matured Callet, this is a delicious, juicy red with a vibrant character all of its own.

The team must have had fun with this blend, and the result is a robust, complex and very drinkable red wine.

Pure Syrah yes, but made from grapes from three different plots, harvested on different dates, combined after malolactic fermentation and put into new French oak to integrate into this satisfying, rich red wine. Syrah lovers will find this vintage a treat.